Piuma Almerico One-seat

The single-seater Piuma Almerico is very similar to the two-seater, obviously with different dimensions; the airfoils are the same as well as the shape of the fuselage and tailplanes.

The high and braced wing has been simplified compared to the two-seater as the flaps no longer necessary have been eliminated because the lower wing loading has made it possible to maintain the stall speed below 65 km/h (40 mph).

A further modification with triple tapering in plan (with winglets that can be disassembled in 10 seconds for the hangar), brings the shape closer to the elliptical one, improving its efficiency.

The fuselage is tapered to the rear under the engine, while the aluminum alloy tail boom has a light wooden fairing that gives the boom additional rigidity, while making the fuselage more aerodynamic.

For the prototype, the 60 Hp HKS 700 4-stroke engine was used, designing the engine mount and the spaces for the oil coolers, the oil tank and for the small muffler; unfortunately the engine is no longer in production, but it seems that the U.S.A. company

Quicksilver Aircraft Northeast - Light Sport Aircraft Sales- still ensures continuity for spare parts and has some engines available - for information: email: info@quicksilverne.com

With small adaptations it is possible to use other engines, as long as they do not weigh more than the design weight, even 2-stroke engines, with power between 45 and 60 HP.

The landing gear is a leaf spring in a mixed lamellar ash and fiberglass, light but resistant and drop-profiled, positioned in an almost barycentric area and complete with wheel fairings; a front wheel, which can be operated with the pedals, allows easy

movement on the ground while a small rear wheel is fixed to protect the tail.

The use of a ballistic or pneumatic parachute has been foreseen with the attachment in the anchor plates of the wing struts; for its positioning it is advisable to make use of the experience of the manifacturer of the parachute itself.

With a cruising speed of around 150 km/h(mph 90) and a reliable and with low consumption 4-stroke engine, the Almerico is able to compete with industrial machines costing many times more: the intrinsic stability, the ergonomic seat, the glider-type cantilever

with a good instrumental equipment together with abundant internal dimensions even for pilots of considerable weight and height make navigation comfortable and pleasant.

Basic peculiarities

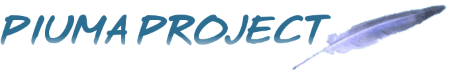

- Airfoil, chord and winglet: the airfoils are glider-like: FX 61-168 (16.8% thick at 37% chord) at the root and FX 60-126-1 at the tip, twisted about 3° negative; the maximum chord is 1000 mm (39”) and the wingspan is 12 meters (ft 39,4),

with 3 tapers.

- The wing covering is in birch plywood with 45° application and internal stiffeners with styroform in the front area; the ailerons are only covered with dacron as well as a small area near the trailing edge.

- Air brakes: they are made in a set back position with respect to the spar so as to limit the movement of the center of pressure of the wing during their use (less trim variations); the hinge and drive mechanisms are the same as those of

the two-seater and allow for effortless and highly effective operation.

- Ailerons: The movement is with a rigid bar and the hinging is central as in the two-seater for better aerodynamics and efficiency.

- Trailing edge of wings and rudders: a shaped profile in carbon fiber was self-built, light, thin and perfectly straight, made on aluminum molds 3 meters long: instructions and photos are in the plans.

Wing Span

Wing Area

Length

Height

Empty Weight

Gross Weight

Fuel Capacity

HP/HP (range)

V.N.E.

Top speed

Cruise

Stall speed

L/D max

Aspect ratio

Min. Sink rate (50 mph)

Load factors (breaking)

Load factors (security coeff. 2)

Take-off

Landing

Bldg Time (man hours) |

39.4 ft.

106 sq.ft.

20 ft.

5.6 ft.

440 lbs.

660 lbs.

11 gal

60 (50/60)

112 mph.

100 mph.

90 mph.

40 mph.

25

14.9

165 ft/min.

+7.5 -2

+3.75 -1

330 ft.

330 ft.

1200 |

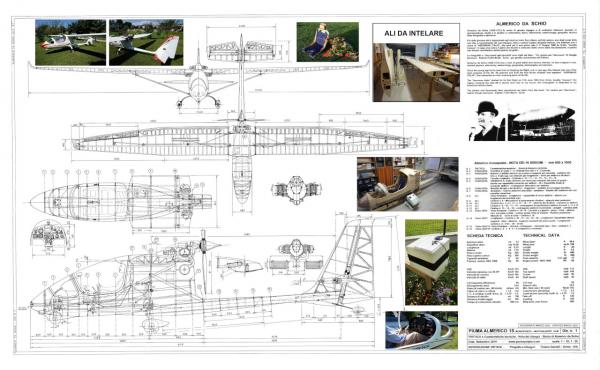

Construction Plans

The

Construction Plans consist of the following:

- N.16 detailed drawings large approximately 100 x 60 cm (40’ x 24’) , with some photos.

- The Construction Book is 60 pages (with 97 photos and drawings); it teaches step by step how to proceed in the works with various information about wood, plywood, glues, aluminum alloys, Dacron, paint, general electrical as well

as instructions for the trim.

The first 42 pages are dedicated to materials and equipment and to the various parts to be built and to assembly; follows the detailed note of all the necessary materials, the calculation of the center of gravity and the instructions for the

first flights, as well as the check-list of the pre-flight checks and a hypothesis of weights for the parts to be built.

- The Project Book which in over 94 pages of calculations with more than 140 photos, tables, drawings and graphs, illustrates how the Almerico was born, verifies the sizing of the resistant structures, exhibits the verification

calculations, as well as those for the Drag, Lift , Moment and Efficiency at various speeds; calculations of VD, VNE, VA, and Stall speed follow.

- There is a DVD with 1500 photos of the complete Piuma Almerico Mono prototype with a lot of details being built by the designer, with photos of the various assemblies.

- Also included is a DVD with 3800 photos of the construction phases of the various Piuma, including the Almerico 2 seats, many photos of the completed and flying single-seater and two-seater Piuma and some in-flight videos, as well

as a detailed note of all the necessary aluminum alloy construction parts.

- Also included are the CAD drawings for water or laser cutting of all the flat metal parts, which can be made in these ways.

- There is also a file with CAD drawings for waterjet or laser cutting of all the frames in birch plywood, the noses of the ribs and some smaller ribs all in birch plywood; this greatly shortens the construction of these

details..

Other useful information for the builders

The cost of materials, excluding engine and instruments, is around 6000 $ (at 2023 prices); the cost of the engine and of the instruments is quite variable, depending on the choice of the type of new or used engine and on the more or less

essential instrumentation.

The tail boom is made of 6005-T16 aluminum alloy: you need a tube at least 5.75 m (226”) long with an external diameter of 127 mm (5”)- thickness 1.5 mm (1/16”) ; by adapting the fuselage fittings, it is also possible to use slightly different

tubes, as long as their bending strength is not lower than that of the tube above (bending strength values are in the Project book).

The construction time can be estimated at around 1200 hours, having the metal parts made in a workshop.